Development of cellulose fibre moulding materials with a biomass content of over 90%

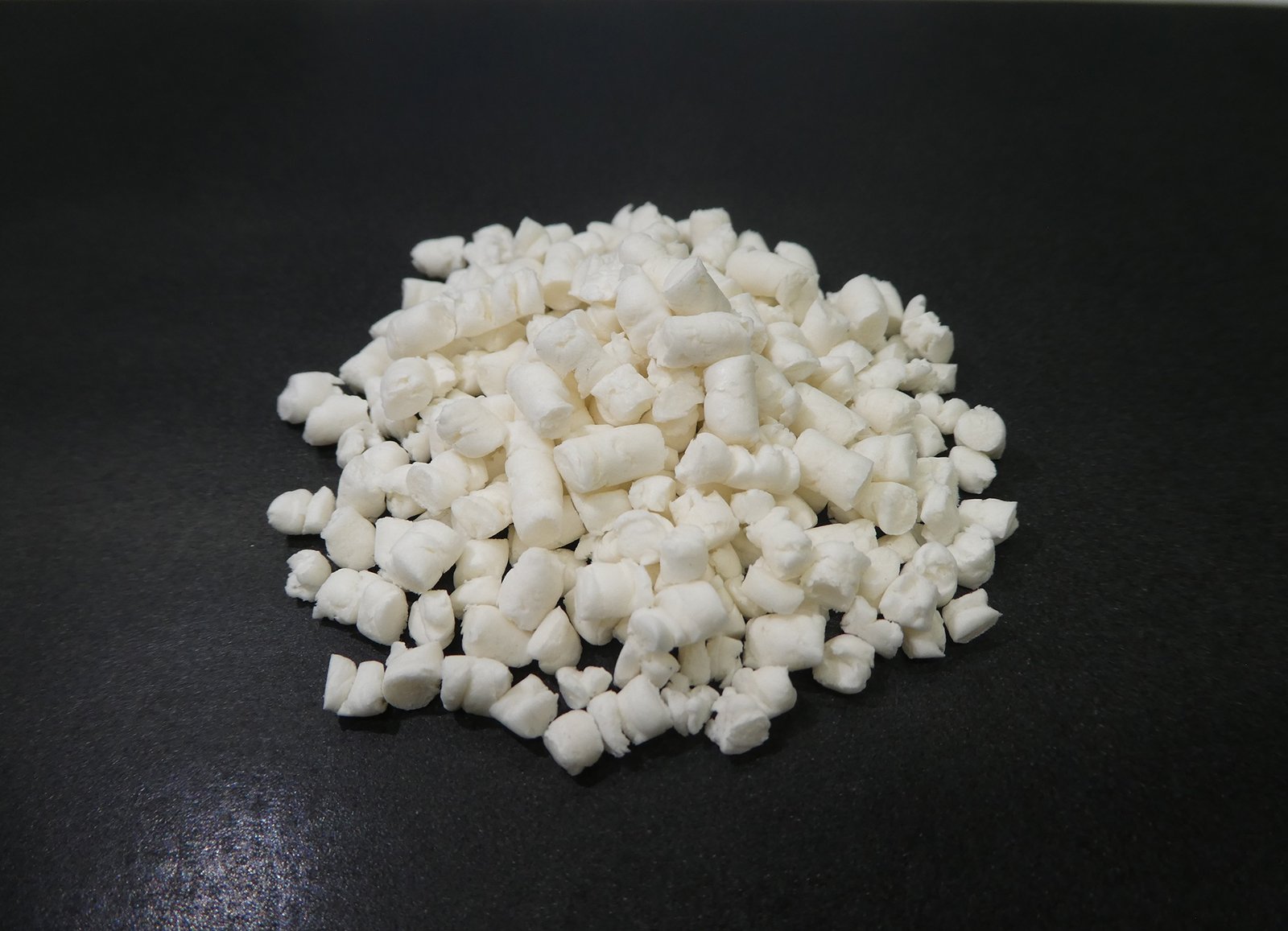

The Manufacturing Innovation Division of Panasonic Corporation has developed a moulding material [2] with a biomass content [1] of 90% or more by applying the technology developed so far for mixing plant-derived cellulose fibres into resin in high concentrations to plant-derived resin (biopolyethylene). By adding a high concentration of cellulose fibres to soft biopolyethylene, we have succeeded in achieving strength equivalent to that of conventional kinari*1 and also in developing it as a white material.

Due to recent environmental issues such as the marine plastics, depletion of oil resources and global warming, the efficient use of natural resources (SDG 12) and the prevention and significant reduction of marine pollution (SDG 14) have been set as UN development goals, and the reduction of resin volumes is required worldwide. In 2017, the Company also formulated its Environmental Vision 2050 and is promoting development activities to achieve both a better life and a sustainable global environment.

In 2015, we started research and development activities to reduce the amount of petroleum-derived resin, and developed a composite processing technology to mix cellulose fibre, a naturally derived component, into resin at a 55% concentration*2 in 2019 and at a 70% concentration (70% biomass content)*3 in 2021. To further increase the biomass content, we have been developing the replacement of petroleum-derived resin (polypropylene) with plant-derived resin*4 and have focused on bio-polyethylene (with a biomass content of over 90%) made from waste molasses, the residue of sugarcane. However, bio-polyethylene has about half the strength of polypropylene, and simply mixing it with cellulose fibres would have resulted in low strength properties, which limited the scope for development. Therefore we added appropriate additives to achieve strength properties equivalent to those of kinari made from polypropylene with a biomass content of 90% or more as a moulding material. In addition, as with the previous kinari, we have succeeded in producing white resin pellets which allows a high degree of freedom in colouring. The material itself can be turned brown during the moulding process, enabling a high design quality to be achieved, such as a woody feel.

In the future, the characteristics and advantages of the highly concentrated cellulose fibre moulding material will be utilised to develop applications for home appliance housings and in-vehicle mechanical components. We'll also leverage the high strength and design flexibility of the material for various usages such as large home appliance exteriors, beauty appliances, clothing and accessories, daily commodities, as well as beverage and food containers. At the same time, by further improving the biomass content, material properties and superiority, we will accelerate the material deployment for a wide range of products, and promote corporate activities through the reduction of resin use to realise a sustainable society.

[Features]

1. Developed highly concentrated cellulose fibre moulding material with a biomass content of 90% or more.

2. Achieved strength properties equivalent to those of conventional kinari.

3. Contribute to the global environment by reducing the amount of resin used, as the main components are of natural origin.

※1:Panasonic Corporation Press Release (Japanese)

1st Dec. 2021 / Starting sample sales of the highly concentrated cellulose fibre moulding material kinari

https://news.panasonic.com/jp/press/data/2021/12/jn211201-2/jn211201-2.html

※2:Panasonic Corporation Press Release (Japanese)

8th Jul. 2019 / Development of highly concentrated cellulose fibre moulding material for high design flexibility

https://news.panasonic.com/jp/press/data/2019/07/jn190708-1/jn190708-1.html

※3:Panasonic Corporation Press Release (Japanese)

4th Feb. 2021 / Development of 70% high density cellulose fibre moulding material

https://news.panasonic.com/jp/press/data/2021/02/jn210204-1/jn210204-1.html

※4:This development was partly funded by a grant from the New Energy and Industrial Technology Development Organisation (NEDO) (JPNP20009).

Applications: Home appliance housings, in-vehicle structural components, daily commodities, beverage and food containers, etc.

Patents: 23 domestic, 33 overseas.

Terminology:

[1] Biomass content: The percentage of plant- and biologically-derived raw materials (biomass raw materials) contained in a material.

[2] Moulding: The process of melting a material and pouring it into a mould to form a product. Materials that can be moulded are referred to as moulding materials.

Press Release

https://news.panasonic.com/jp/press/data/2022/03/jn220318-2/jn220318-2.html

Release date: 18 March 2022