kinari -Panasonic HD develops marine biodegradable cellulose fiber molding material

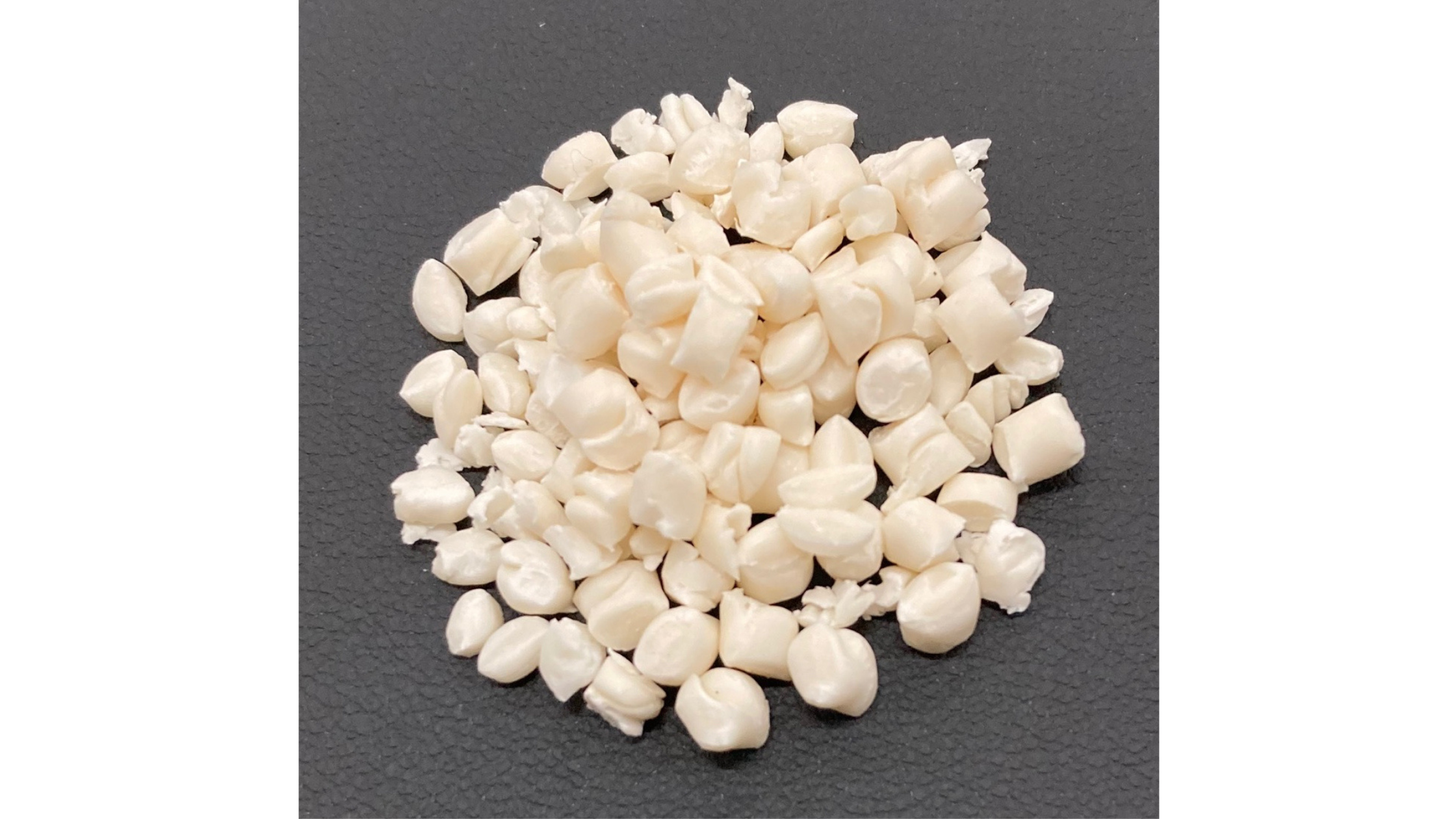

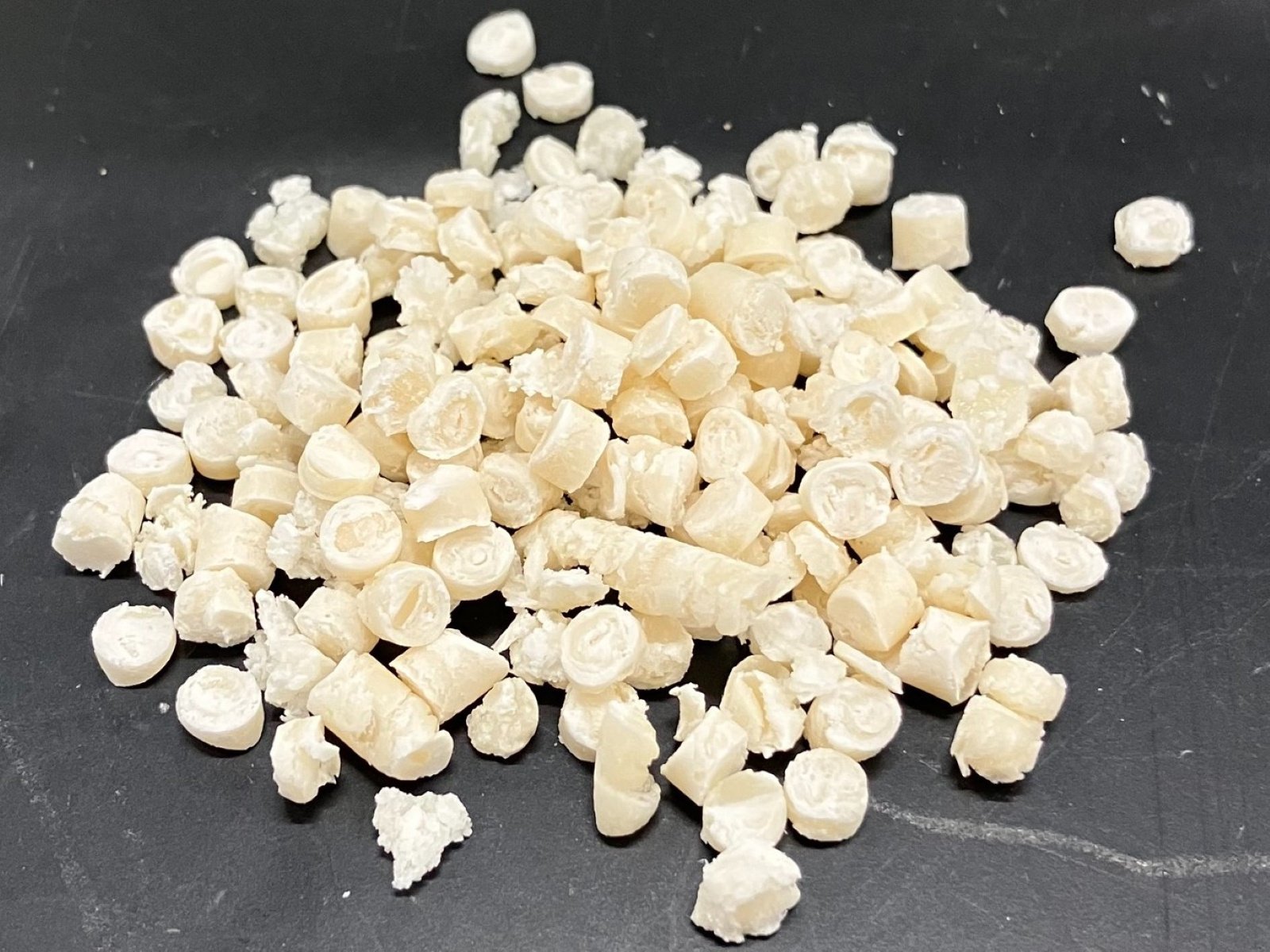

Osaka, Japan, January 7, 2025 – Panasonic Holdings Corporation (Panasonic HD) has developed a molding material with full marine biodegradability by applying the technology the company has been developing to incorporate highly concentrated cellulose fiber derived from plants into resins. By adding plant-derived cellulose fiber at high concentrations to marine biodegradable resins, Panasonic HD has succeeded in developing a molding material that achieves both excellent mechanical properties and marine biodegradability.