Developed a fully biodegradable cellulose fiber molding material

The Manufacturing Innovation Division of Panasonic Holdings Corporation, has developed a fully biodegradable molding material (2) by applying its previously developed technology for blending a high concentration of plant-derived cellulose fiber into resins to biodegradable plant-derived resins (polylactic acid) and other materials. By adding a high concentration of cellulose fiber to biodegradable resin, we succeeded in developing a molding material with excellent mechanical properties and biodegradability.

Recent environmental problems, such as marine plastic problems and the depletion of oil resources and global warming, have led to the establishment of UN development goals for efficient use of natural resources (SDGs Goal 12) and prevention and significant reduction of marine pollution (SDGs Goal 14), which calls for a worldwide reduction in the amount of resins.

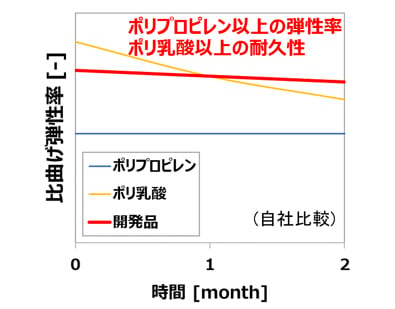

In 2015, our company began R & D activities to reduce the amount of petroleum-based resins, and in 2019 developed a composite processing technology that mixes cellulose fiber, a naturally occurring component, into resins at a concentration of 55% * 1, in 2021 at a concentration of 70% (with a biomass of 70%) * 2, and in March 2022 developed a molding material using plant-based resins with a biomass of 90% or more * 3. In addition, we worked to incorporate cellulose fibers into biodegradable resins to achieve complete biodegradation of molding materials. Existing biodegradable resins are less strong and durable than general-purpose resins such as polypropylene, limiting their applications. Furthermore, when mixed with cellulose fiber, fluidity is low and complex shapes are difficult to form, so deployment locations were limited. Therefore, by blending several biodegradable resins, including plant-derived polylactic acid, and adding appropriate additives, we have developed a molding material that achieves both biodegradability and high modulus of elasticity, even for thin-walled moldings of 1 mm. In addition, as with the conventional kinari (55% cellulose fiber) * 4, the material has been successfully pelleted into a white resin with high coloration freedom, and the material itself can be browned to achieve a high degree of woody texture and other design qualities.

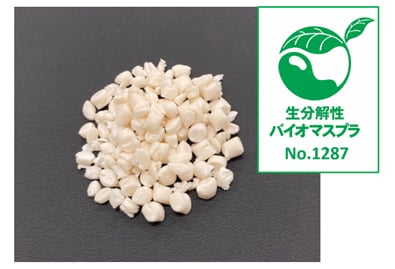

The molding material developed has received the Biodegradable Biomass Plastic mark * 5 certified by the Japan Bioplastic Association.

In the future, we will take advantage of the features and advantages of fully biodegradable cellulose fiber molding materials to expand into home appliance housings and in-vehicle mechanism members, big-name home appliance exteriors and beauty appliances that take advantage of their high strength and design, clothing and daily necessities, and beverage and food containers. Through these initiatives, we will promote corporate activities aimed at realizing a sustainable society through the reduction of resin usage.

The molding materials developed will be exhibited at the EcoPro exhibition at Tokyo Big Sight (December 7, 2022 to 9) as a joint exhibit with the Clean Ocean Materials Alliance.

Features:

1. Developed a highly concentrated cellulose fiber molding material that is completely biodegradable

2. Both strength and biodegradability equal to or greater than conventional kinari

3. Contributing to the global environment by reducing the amount of resin used because the main ingredients are naturally derived

|

|

| Fully biodegradable cellulose fiber molding material | Compacts made with fully biodegradable cellulose fiber molding material |

|

![ポリプロピレン、ポリ乳酸、開発品のコンポスト[3]に おける生分解速度](https://blog.ppe-biz.com/hs-fs/hubfs/CeF/%E3%83%97%E3%83%AC%E3%82%B9%E3%83%AA%E3%83%AA%E3%83%BC%E3%82%B9/jn221206-1-5.jpg?width=395&height=309&name=jn221206-1-5.jpg) |

| polypropylene, polylactic acid, at 50% humidity in the developed product Elastic modulus over time | In polypropylene, polylactic acid and compost of the developed product, 3 biodegradation rates |

*1: Panasonic Group Press Release

July 8, 2019 Developed high-density cellulose fiber molding material for high design quality

https://news.panasonic.com/jp/press/data/2019/07/jn190708-1/jn190708-1.html

*2: Panasonic Group Press Release

February 4, 2021 70% Developed high-density cellulose fiber molding material

https://news.panasonic.com/jp/press/data/2021/02/jn210204-1/jn210204-1.html

*3: Panasonic Group Press Release

March 18, 2022 Developed a cellulose fiber molding material with a biomass of at least 90%

https://news.panasonic.com/jp/press/jn220318-2

*4: Panasonic Group Press Release

December 1, 2021: Sales of samples of kinari, a highly concentrated cellulose fiber molding material, begin.

https://news.panasonic.com/jp/press/data/2021/12/jn211201-2/jn211201-2.html

*5: Products that meet the Japan Bioplastics Association's criteria for identification and labeling of biomass plastics among biodegradable plastics are permitted to use the name and mark "Biodegradable Biomass Plastic."

http://www.jbpaweb.net/identification/

Use:

Home appliances, automotive structural components, daily necessities, beverage and food containers, etc.

Patents:

Domestic 23 Overseas 33

Press release:

https://news.panasonic.com/jp/press/jn221206-1

Release date: December 6, 2022