70% High-Concentration Cellulose Fiber Molding Material, Kinari, Begins Sample Sales

In April 2023, Panasonic Production Engineering Co., Ltd. will start selling samples of kinari * 1 (Below, omitted as kinari70), a molding compound made from 70% plant-derived cellulose fiber and resin, developed by the Manufacturing Innovation Division of Panasonic Holdings Corporation.

In its long-term environmental vision for a sustainable future, "Panasonic GREEN IMPACT," the Panasonic Group is aiming for an impact reduction of "approximately 1% (300 million tons)" of total global CO2 emissions by 2050. As one of these initiatives, since 2015, we have been developing materials using naturally-derived cellulose fiber with the aim of reducing our environmental impact by reducing the use of petroleum-derived resins. In 2019, the company succeeded in compounding cellulose fibers, which tend to brown, into a white material through a processing technique that mixes more than 55% of the fibers into the resin. In February 2021, we also succeeded in developing a molding material in which cellulose fiber is mixed into resin at a high concentration of 70% to further reduce the amount of petroleum-derived resin * 2.

In December 2022, we launched mass production sales * 3 of a molding material made of 55% cellulose fiber composite (product name: kinari55 PP), which is used by many customers. We will also start selling samples of the kinari70 molding material in April. We will also provide production goods (molds, molding processes, etc.) in response to customer requests, and take advantage of the high strength and design characteristics of highly concentrated cellulose fiber molding materials to develop products that both contribute to the environment and create new product value for various industries, such as consumer electronics housings, automotive components, housing interior components, and clothing, daily necessities, and food containers.

Features of the kinari70

Cellulose fiber, a natural fiber, is combined with resin (polypropylene) at a high concentration of 70% to achieve both strength and biomass.

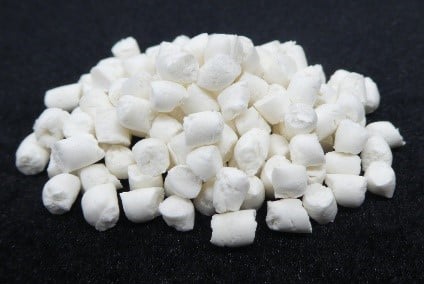

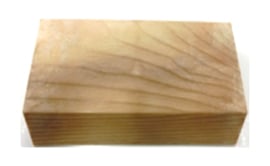

The material (pellet) is white even at high concentration, and the degree of freedom of coloring is as high as that of 55% material. Also, woody design can be realized by forming process technology.

Improves fluidity, which is a problem with high concentration, and enables thin-walled processing in injection molding.

|

|

|

| kinari 70 pellets | by molding process technology Woody feeling design |

Tableware using kinari70 |

*1: "kinari" is a registered trademark of Panasonic Holdings, Inc.

*2: Panasonic Group News Release

February 4, 2021 70% Developed high-density cellulose fiber molding material

https://news.panasonic.com/jp/press/jn210204-1

*3: Panasonic Group Topics

January 26, 2023 Commenced mass production and distribution of "kinari," a high-density cellulose fiber molding material, on Chip One Stop, a mail-order website

https://news.panasonic.com/jp/topics/204999

Press release:

https://news.panasonic.com/jp/press/jn230316-1

Release date: March 16, 2023